|

|

Maintenance Maintenance of GVS products is extremely simple. Products are designed for 24 hours autonomous operation, so maintenance is needed only in the case of failure. System maintenance Basic maintenance is assigned to system operators. Alarm reports inform operators about malfunctions and irregularities in the system. Operators perform simple maintenance tasks according to procedures from the maintenance manual. Operators have at their disposal plenty of commands for working with alarms (system self-diagnostics), and also commands for various procedures, like measurements and statistics, to track the other malfunctions. All commands are described in details in built-in help system. To avoid system downtime during maintenance, there are commands to temporarily stop the operation of one or more system modules, so the rest of the system stays in full operation. Maintenance procedures are covered in system manuals, and there is a training course for maintenance offering deeper knowledge and practical exercise to trainees, guiding them to become system maintenance experts. After completing system maintenance training course, experts can perform complex maintenance tasks. They are capable to correct each and every malfunction in the system, if provided with necessary tools, accessories and spare parts. Both basic and complex - full maintenance may be performed by GVS experts. If that is the case, GVS warranty covers the operation of the complete system. Maintenance contract may include full maintenance, only complex maintenance or the user may perform the maintenance himself. In the case of full maintenance, GVS covers all maintenance costs, like spare parts, repair of replaceable parts, transportation costs and all other costs to keep the system in 100% operational state. Warranty period During warranty period, GVS repairs all malfunctioning parts free of charge. If the part can not be repaired, GVS will deliver brand new part free of charge, except:

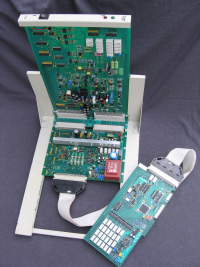

Replaceable parts repair System maintenance does not include replaceable parts repair. When malfunctioning part is replaced by the part from the spare parts set, full operational state of the system is restored and the job of system operator is completed, after he sends the malfunctioning part to repair. GVS manufacturing plant includes a repair center, capable to repair any replaceable part. Specialized experts employed in the repair center have many years of experience in repair of electronics. Besides main repair center, there are regional repair centers, capable to repair all sorts or some sorts of replaceable parts. GVS forms regional repair centers in the areas containing many systems or with high needs for maintenance. Replaceable parts repair terms are defined through the maintenance contract, and there are several starting options:

Stated options may be combined, for example operators repair some sorts of replaceable parts and repair center makes the offers for repair other sorts. Repair terms are not applicable if the parts are damaged by force major, improper handling and other conditions stated with warranty period - in the previous section. Spare parts Quantity of spare parts and their distribution are determined during system dimensioning process, starting from user requirements. Manufacturer recommendations concerning spare parts are included in the engineering manual. GVS stocks sufficient quantities of spare parts for all the systems in operation, providing the users with a possibility to get the spare part they need, when they need it. Additionaly, GVS stocks spare parts 10 years after declaring product end-of-life, or product version end-of-life, and even after that, until the stock is cleared. For repair centers, whether GVS or third-party repair centers and also for customers equipped with GVS test & repair equipment, GVS stocks necessary components and materials, as well as tools and accessories. Because these items are treated as spare parts for GVS specialized test & repair equipment, they are stocked 10 years after declared end-of-life of test & repair equipment. Considering that test & repair equipment lives at least 10 years longer than the system it repairs, minimum support time for test & repair equipment is 20 years after product end-of-life. Actual support time is usually much longer.

|

©2005 – 2023 GVS ko Llc. All rights reserved.